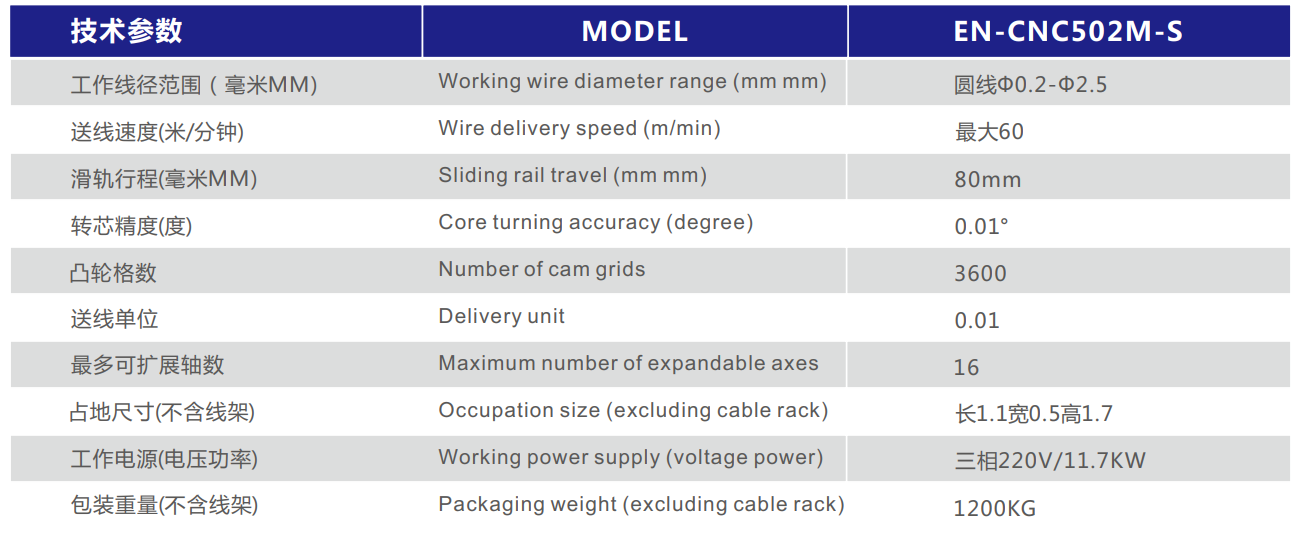

EN-CNC502M-S

專(zhuān)業(yè)電腦彈簧機(jī)械設(shè)備生產(chǎn)廠商,以簡(jiǎn)單易用、生產(chǎn)效率高、運(yùn)行穩(wěn)定的高性價(jià)比和完美高效的售后,占領(lǐng)了主流市場(chǎng)。我們的設(shè)備可以生產(chǎn)常規(guī)拉簧、壓簧、扭簧、寶塔簧、雙扭簧、彈夾彈簧、觸指彈簧、渦卷簧等。

關(guān)鍵詞:

所屬分類(lèi):

機(jī)型詳情

特性 / FEATURES:

•滑座1可左右移動(dòng),行程20MM

•所有滑座均為獨(dú)立伺服驅(qū)動(dòng),提高調(diào)試產(chǎn)品的效率。

•滑座材質(zhì)采用高耐磨度合金鋼材,延長(zhǎng)滑座運(yùn)轉(zhuǎn)的使用周期。

•動(dòng)平衡化的送線轉(zhuǎn)線機(jī)構(gòu),高速、精準(zhǔn)。采用歐盟CE標(biāo) 準(zhǔn)的防護(hù)罩。

•伺服滑座單元可彈性配置,根據(jù)客戶實(shí)際需要增減,以 達(dá)最佳性價(jià)比、

•通用的模組界面,以往的充備工裝可以共用,節(jié)省了工 裝損耗。

•源自臺(tái)灣的設(shè)備技術(shù),優(yōu)化后的操作系統(tǒng),保證了產(chǎn)品 的一致性。

•也可升級(jí)增加多工位卷曲、伺服剪刀和輔助卸料的傳輸 裝置等。

•標(biāo)配11軸

•Sliding seat 1 can move left and right, with a stroke of 20MM

•All slides are independently servo driven, improving the efficiency of product debugging.

•The material of the slide seat is made of high wear resistant alloy steel, which extends the service life of the slide seat operation.

•Dynamic balancing wire transfer mechanism, high-speed and precise. Adopting the EU CE standard protective cover.

•The servo slide unit can be flexibly configured to increase or decrease according to the actual needs of customers, in order to achieve the best cost-effectiveness

•The universal module interface allows for the sharing of previous charging fixtures, saving tooling losses.

•The device technology originating from Taiwan and optimized operating system ensure product consistency.

•It is also possible to upgrade and add multi station curling, servo scissors, and auxiliary unloading conveyor devices.

•Standard 11 axis configuration

相關(guān)機(jī)型